Technical information

Certificates

Request information

PRESS-MULTI system

PRESS FITTINGS FOR MULTILAYER PIPES

The fittings AC-FIX PRESS-MULTI are made of brass for machining CuZn39Pb3 (CW614N) and brass for forging CuZn40Pb2 (CW617N). The sleeve is made of stainless steel. The body surface of the fitting is nickel (Ni) plated.

The fittings AC-FIX PRESS-MULTI are manufactured according to UNE-EN-1254-1/3:1999 and to UNE-

EN-ISO 21003:2008, the manufacturing system is certified ISO: 9001 by DQS of Germany (IQNet).

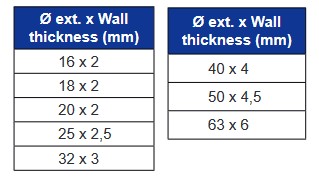

They are compatible with multilayer pipes with the following sizes and tolerances:

The pipes must be manufactured according UNE-EN- ISO 21003.

These fittings have been designed for greater easiness and speed of assembly:

- Fittings DN 16-32 are designed specifically for pressing with jaws U, H, RF y RFz.

- Fittings DN 40, 50 and 63 are designed specifically for pressing with jaws U.

- Our O-Rings are manufactured according to DVGW-W534. This German standard issued by DVGW applies in particular to the seals (O-Rings) which are intended to be used in press fittings and in contact with hot water. It includes a compression set test in water of 3000h at 110°C with a value survey every 1000h. This test has the intention of evaluating the material behaviour over quite a significant period of time. The maximum compression set admitted value is 40%. The maximum compression set value of our O-Rings is below 40% and therefore they are highly resistant.

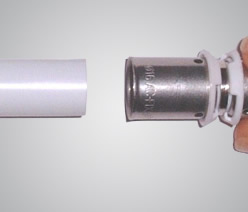

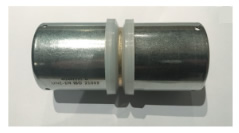

- The check holes on the sleeves (3 at 120º) allow the user to check that the fitting has been completely inserted into the pipe.

- The sleeve is pre-assembled with a plastic part. It increases the easiness and quickness of the assembly and also indicates where to put the side of the pressing jaws. This pastic part avoids the contact between the aluminium of the pipe and the brass of the fitting (dielectric protection).

- All the threaded parts have an hexagonal design so they can be tightly held with a spanner when assembling male and female threads.

- These fittings absorb safely the variations of the sizes of the plastic pipes that may happen due to the manufacturing tolerances of the pipes or to the differences of temperature of the transported fluids.

- These fittings have a high resistance to corrosion (internal and external).

- Safety of the assembly: the fitting has two O-Rings. It is necessary to calibrate and chamfer the pipe before inserting the fitting into, in order not to damage the O-Rings. Once the assembly is finished, the sealing achieved is permanent. The fittings can be pressurized immediately after being assembled

TOOLS

- High level of quality and safety.

- Optimum handling.

- Systems that avoid 100% the risk of leaks.

- Wide range of spare parts in stock.

IMPORTANT

We advise you to avoid the use of hemp to seal the threads. In case of using Teflon tape (PTFE), we recommend to put between 8 to 10 laps. It is preferable not to put Teflon in the first thread. When connecting water pipes, make sure that threaded connections are not subjected to excessive mechanical stress. Over time this may result in breakage, with loss of water and damage to people and/or property.

We recommend that the tightening torque of the threaded parts does not exceed 30 Nm.

PRESURE TEST

The finished installation with the pipes at sight (before being hidden by masonry, filler o insulating material) must be subject to the hydrostatic pressure test of pipeline networks (pressure test) in accordance with local regulations. After the pressure test, the pipes of the drinking water installations should be thoroughly washed.

FIELD OF APPLICATION

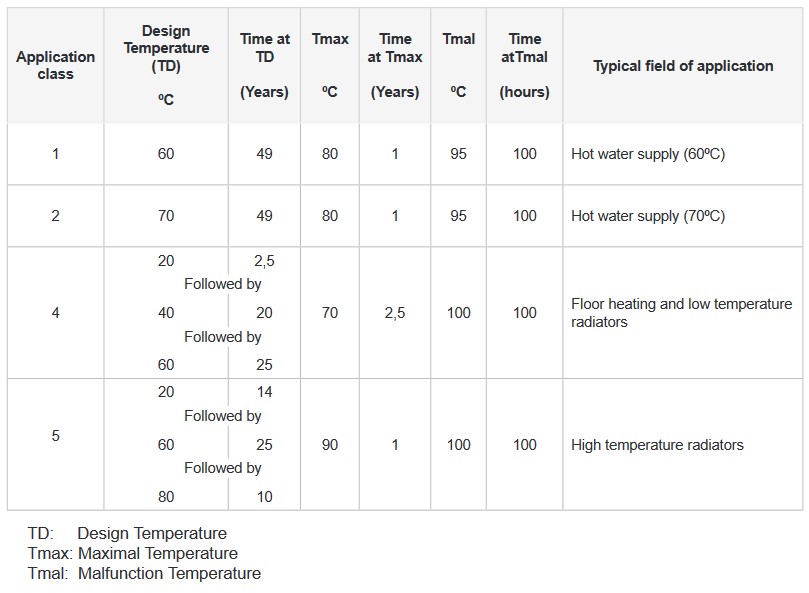

These fittings have been designed to be used with Multilayer pipes in the following applications as they are defined in the norm ISO 21003:2008:

Where more than one design temperature appeas for any class, the times should be aggregated (e.g. the design temperature profile 50 years for class 5 is: 20ºC for 14 years followed by 60ºC for 25 years, 80ºC for 10 años, 90ºC for 1 year and 100ºC for 100h).

The water used in the installations must come from the supplyying network

ASSEMBLY STEPS DN 16 AT 32

1

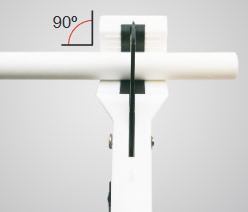

Cut the pipe as clean and perpendicular as possible to its axis

2

It is necessary to calibrate and chamfer the pipe inside in order

not to damage the O-Rings of the fittings. The AC-FIX chamfering tool

chamfers and calibrates the pipe.

3

Insert the fitting into the pipe. The pipe must be seen through the

check holes of the sleeve.

4

Place the side of the jaw beside the plastic ring and press

Important:

The fittings AC-FIX PRESS-MULTI can be pressed with jaws or inserts type U, H, RF and RFz. For pressing with jaws or inserts type TH, contact our technical department

ASSEMBLY STEPS DN 40, 50 AND 63

1

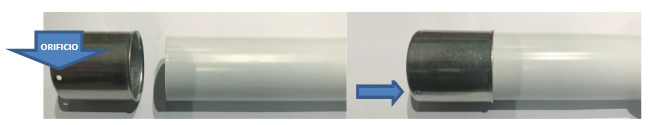

When you unpack the bag, you will see the position of the fitting is like the picture. Check holes are on the outer end of the stainless steel sleeve

2

When you use the fitting, first pull out and turn down the sleeves

like the picture, making sure that when pulling the sleeve, the plastic

ring does not detach from the body of the fitting

3

The pipe must be well cut, perpendicularly to its axis. Then, use the reamer

to chamfer the pipe.

4

Put the sleeve on the pipe and make sure the check hole is at the end of pipe

Please make sure the pipe is inserted to the end of the sleeve so you can see the pipe through the check holes

5

Then, insert the fitting body into the pipe with sleeve. Insert it carefully and check visually that the O-Rings are not damaged

6

Make sure you can see the pipe through the check holes and make sure it is

inserted to the end of the fitting body.

7

Press with U type jaws or rings. Place the side of the jaw beside the plastic ring and press. The plastic ring should not be pressed