PRESS DUO SYSTEM FOR PEX AND MULTILAYER PIPE

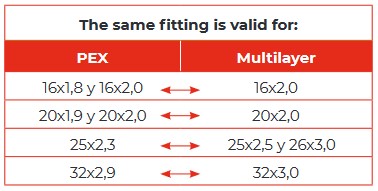

The fitting DN 25 and DN 26 have the same body, the only change is the stainless steel sleeve.

AC-FIX PRESS DUO fittings don’t use O-Rings. This fact::

- Avoids the problems of leaks due to the damage of O-Rings that can happen when inserting the fittings into the pipes.

- Avoids the problems of leaks due to the aging of O-Rings.

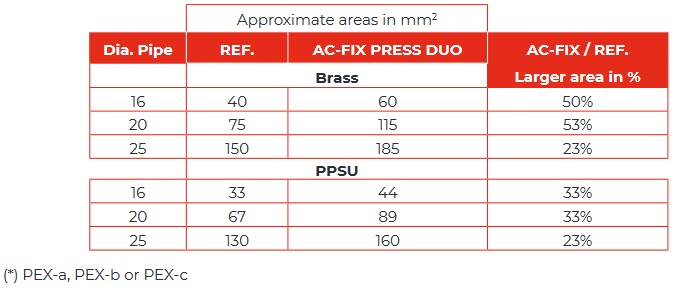

- Allows a better flow of water compared to many fittings with O-Rings because the inner diameter of the AC-FIX PRESS DUO fittings is larger than in fittings with O-Rings with similar characteristics (material of the fitting, resistance to pressure, etc.).

- The function “LBP” (“Leak Before Press”) is achieved: the fitting that has not been pressed leaks even at very low water pressures which is very useful to easily detect possible leaks due to lack of pressing when carrying out the tests. installation pressure.

- Compared to traditional Press Fittings that achieve sealing only at the points of the O-rings, the PRESS DUO system is watertight throughout the length of the insert.

COMPARISON OF CROSS-SECTIONAL INSIDE AREAS OF PRESS FITTINGS FOR MULTILAYER PIPES

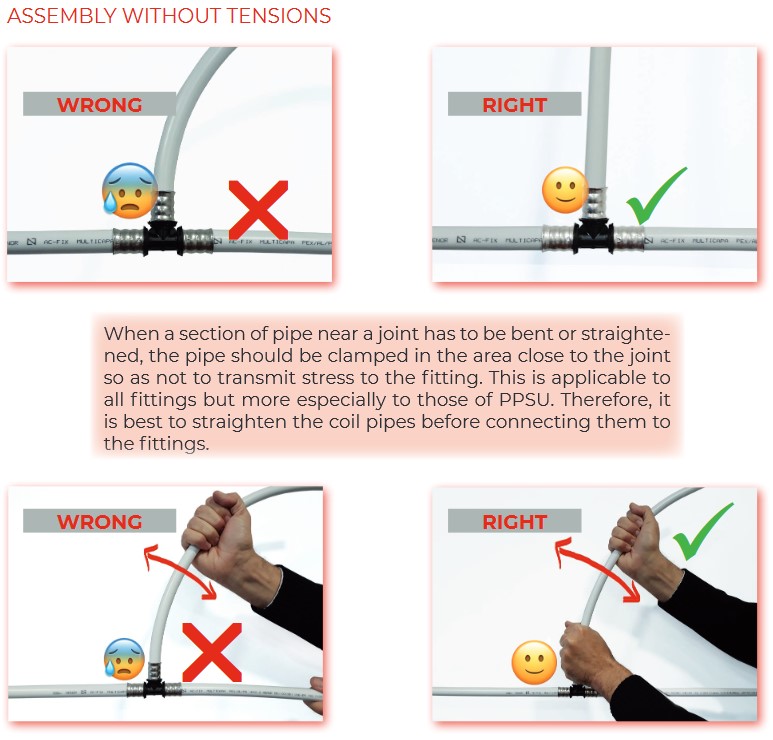

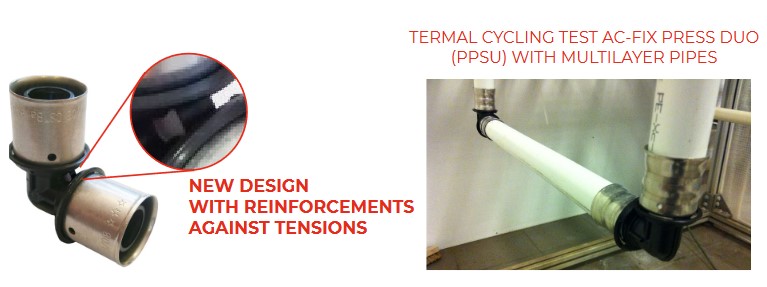

These fittings have been designed for greater safety, easiness and speed of assembly:

- Pressing with PEX pipes: RF, RFz, U, H, CO y VX.

- Pressing with MULTILAYER pipes: U, TH, RF y RFz(*).

(*) We do not recommend pressing with Multilayer pipes with RF or RFz jaws in case of installations DN 32 with design pressure = 10 bar.

The check holes on the sleeves (3 at 120º) allow the user to check that the fitting has been completely inserted into the pipe. - The sleeve is pre-assembled with a plastic part; it increases the easiness and quickness of the assembly and also indicates where to put the side of the pressing jaws.

- The plastic sleeve holder has also the function of dielectric protection for multilayer pipes.

- Safety of the assembly: there is no O-ring. It is not necessary to calibrate and chamfer the pipe before inserting the fitting into. Once the assembly is finished, the sealing achieved is permanent. The fittings can be pressurized immediately after being assembled.

PRESS FITTINGS MADE OF BRASS FOR PEX AND MULTILAYER PIPES

AC-FIX PRESS DUO fittings are made of brass for machining CuZn39Pb3 (CW614N) and brass for forging CuZn40Pb2 (CW617N). The sleeve is made of stainless stel.

AC-FIX PRESS fittings have a quality certificate with nº14/16-2196 issued by the CSTB (the CSTB is the French approval body for the construction sector).

They are manufactured according to UNE-ISO-15875-3/-5:2004.

The manufacturing system is certified ISO 9001 by DQS of Germany (IQNet).

PRESS FITTINGS MADE OF PPSU FOR PEX AND MULTILAYER PIPES

The fittings AC-FIX PRESS DUO made of PPSU are compatible with PEX and MULTILAYER pipes with the dimensions specified before in the pipes technical information of the AC-FIX PRESS DUO fittings made of brass.

They have the same field of application as the fittings AC-FIX PRESS DUO made of brass (see the technical information of the fittings made of brass and instructions for assembly of AC-FIX PRESS DUO fittings).

The fittings AC-FIX PRESS DUO made of PPSU, have the followings advantages:

- High resistance to corrosion.

- Lower pressure drop.

- Much lighter than the brass fittings (the density of PPSU is approximately 1.300kgs/m3 and the density of brass is 8.400kgs/m3).

- Competitive prices due to lower cost of processing

The fittings AC-FIX PRESS DUO made of PPSU can be used for drinking water: the PPSU is an advanced plastic totally odourless and tasteless.

Some chemicals can damage the fittings made of PPSU. Please contact our Technical Department.

TOOLS

- High level of quality and safety.

- Optimum handling

- Systems that avoid 100% the risk of leaks.

- Wide range of spare parts in stock.

IMPORTANT

PRESSURE TEST

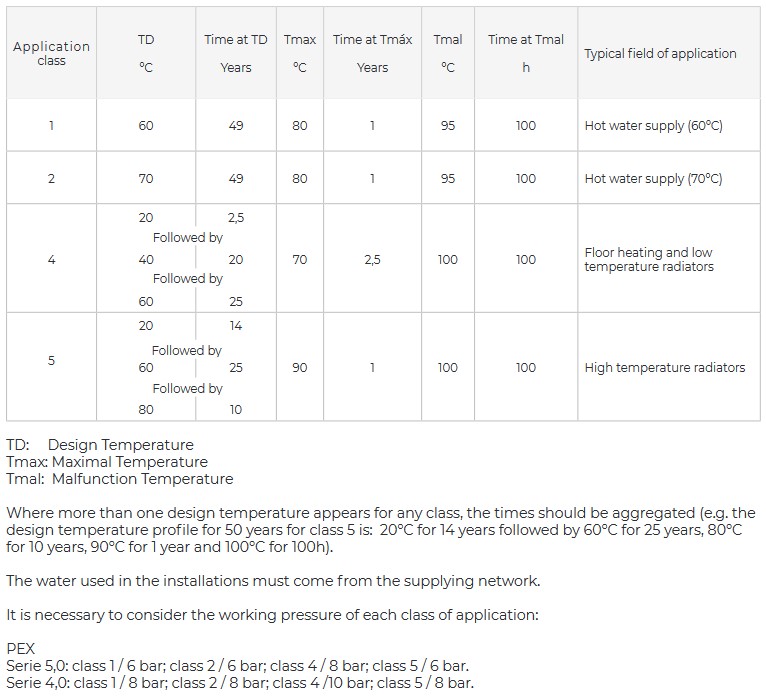

FIELD OF APPLICATION

ASSEMBLY STEPS FOR PEX PIPES

1.Cut the pipe as clean and

perpendicular as possible to its axis

2 Insert the fitting into the pipe.

The pipe must be seen through the

check holes of the sleeve

3 Place the side of the jaw beside

the plastic ring and press with U, RF

or RFz jaw. The plastic ring should

not be pressed.

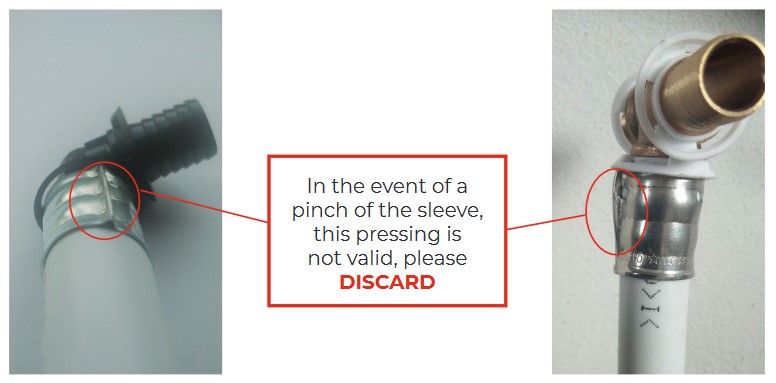

Remark

- The assembly of the fittings AC-FIX PRESS DUO made of PPSU is done in the same way as the assembly of the fittings AC-FIX PRESS DUO made of brass.

- Study our list of compatible tools to press AC-FIX PRESS fittings

PASOS DE MONTAJE CON TUBOS MULTICAPA

2 Separate the stainless steel sleeve from the body of the fitting. Leave the plastic ring (black or white) on the body of the fitting.

3 Put the stainless steel sleeve on the pipe until reaching the end and the pipe can be seen through the check holes and the check holes are completely covered by the pipe

4 Using the special pipe expander(*) recommended for this application, expand the pipe until it meets the resistance of the stainless steel sleeve. DON’T APPLY TOO MUCH FORCE because excessive force could cause an expansion of the sleeve.

(*) Expander codes 100.0005.91 or 100.0005.54.

5 Insert the fitting completely. The pipe must be seen through the check holes of the stainless steel sleeve. The end of the stainless steel sleeve must reach the plastic ring (black or white). Don’t leave more than 1,5 mm between the end of the stainless steel sleeve and the plastic ring.

6 Press with U or TH jaws. If TH jaws are used, the side of the jaw must be placed on the plastic ring