Technical information

Use and assembly instructions

Certificates

Request information

AC-FIX PLASTIC RING FITTINGS FOR PEX-a PIPES

The AC-FIX PLASTIC RING system provides a complete, quick, easy and safe solution for all types of plumbing and heating installations. The AC-FIX PLASTIC RING fittings offer the following advantages over other systems:

- Safety of the assembly: No O-rings are needed. Once the assembly is finished, the sealing achieved is permanent and the set is suitable for embedding.

- The union has the same compression force on all the surface of the insert.

- It is not necessary to calibrate and chamfer the pipe.

- These fittings have a larger inner diameter, allowing the water flow to increase up to 20% more than most of the other different systems and ensuring minimal pressure drop.

- We have available the AC-FIX plastic ring of PEX-a without stop edge. Thanks to the absence of stop edge, the mentioned plastic ring can slide a little bit on the pipe while expanding it. This allows to check visually that the pipe end has reached the shoulder of the fitting.

- Considering the cost of materials and the very low labor cost thanks to its quick assembly, this system offers a maximum profitability.

- These fittings absorb safely the variations of the sizes of the plastic pipes due to the manufacturing tolerances of the pipes or to the differences of temperature of the transported fluids.

- These fittings have a high resistance to corrosion (internal and external).

The thermo-elastic memory of the PEX-a material makes it such a safe system that it improves over time as both the pipe and ring are constantly pushing against the fitting. After expanding the material, the pipe and the ring return to their original form, creating an absolutely watertight connection between the pipe and fitting.

All the components (PEX-a pipes, fittings made of brass or PPSU, plastic rings and assembly tools) of the AC-FIX PLASTIC RING system are fully intercompatible with all the components of the Quick and Easy system of Uponor®*.

The AC-FIX PLASTIC RING system, composed of its fittings made of brass or PPSU, plastic rings and PEX-a pipes, is fully certified by AENOR (Asociación Española de Normalización y Certificación).

BRASS FITTINGS

The AC-FIX PLASTIC RING fittings are made of brass for machining CuZn39Pb3 (CW614N) and brass for forging CuZn40Pb2 (CW617N).

The AC-FIX PLASTIC RING fittings are manufactured according to UNE-ISO-15875-3/-5:2004, reference standard for plastic piping systems for cold and hot water installations (PE-X) and stipulated in the CTE (Código Técnico de la Edificación) and mandatory (according to R.D. 314/2006, from March 17). The manufacturing system is certified ISO 9001 by DQS of Germany (IQNet).

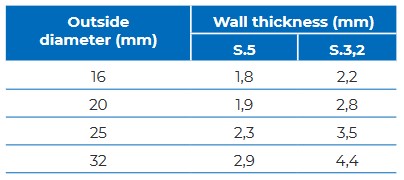

They are exclusively compatible with AC-FIX or Uponor®* PEX-a pipes (according to EN-ISO 15875-2), with the following sizes

To guarantee the integrity of the brass fittings and valves of the AC-FIX PLASTIC

EXPANSION RING system, all the nipples are delivered protected by a cover in order

to avoid possible damage during their handling. This cover shows the diameter of

the nipple on its surface.

*Trademark(s) not related with AC-FIX (Global Piping Systems, S.L.)

PPSU FITTINGS

The AC-FIX PLASTIC RING fittings of PPSU are incredibly durable and resistant, withstanding strong impacts without fracturing and resistant to chemicals of building materials. The PPSU (polyphenylsulfone, of black color) is a high performance plastic, absolutely odorless and tasteless, so it’s completely suitable for use with drinking water.

Like the brass fittings, the AC-FIX PLASTIC RING fittings of PPSU are exclusively compatible with AC-FIX and Uponor®* PEX-a pipes which have the dimensions specified above in the compatibility chart of pipes for AC-FIX PLASTIC RING fittings.They have the same fields of application and the type of assembly is identical to the brass fittings (see technical information and assembly steps of AC-FIX PLASTIC RING).

- Up to 7 times lighter than brass fittings (PPSU density is 1.300 kg/m3 against 8.400 – 8.700 kg/m3 of brass).

- The PPSU is a much better thermal insulator than brass or copper.

- Chemical resistance: this material is resistant to mineral acids, alkaloids and salt solutions. Resistance todetergents and hydrocarbon oils is good, even at high temperatures under moderate pressure levels. Organic compounds, other than ketones, don’t seriously affect this material. These materials should be avoided: esters, ketones, chlorinated methylene, trichlorethylenes, cyclohexane, tetrachlorethylene, toluene, xylene and benzene**.

- No problems of galvanic corrosion and oxidation. Unalterable to chlorinated water and construction materials.

- Water resistance: this material is not affected by hydrolysis.

- Lower pressure drop than brass fittings due to a very low internal roughness that confers a high resistance to scaling.

- Safety: zero migration of metal oxides to water.

- High breaking resistance: the PPSU fittings are capable of absorbing strong impacts, withstand high bursting pressures and can increase their lenght between 50% and 100% before breaking.

- Ideal for silent installations due to its great sound insulation.

- More competitive price than brass fittings due to lower production cost.

PEX-A PLASTIC RINGS

We have available plastic rings made of PEX-a, a high density crosslinked polyethylene that ensures that the ring can expand and contract safely. The AC-FIX plastic rings have a special thickness, larger than the normal pipes to ensure a perfect closing and sealing.

In addition, the marking of the rings is available in three colors: blue for cold water, redfor hot water and black for installations seeking to be more discreet. Rings with blueand red marking also incorporate a point of the same color on the opposite side of the ring for an easier identification from any point of view.

TOOLS

IMPORTANT

PRESSURE TEST

The finished installation with the pipes at sight (before being hidden by masonry, filler o insulating material) must be subject to the hydrostatic pressure test of pipeline networks (pressure test) in accordance with local regulations.

After the pressure test, the pipes of the drinking water installations should be thoroughly washed.

*Trademark(s) not related with AC-FIX (Global Piping Systems, S.L.)

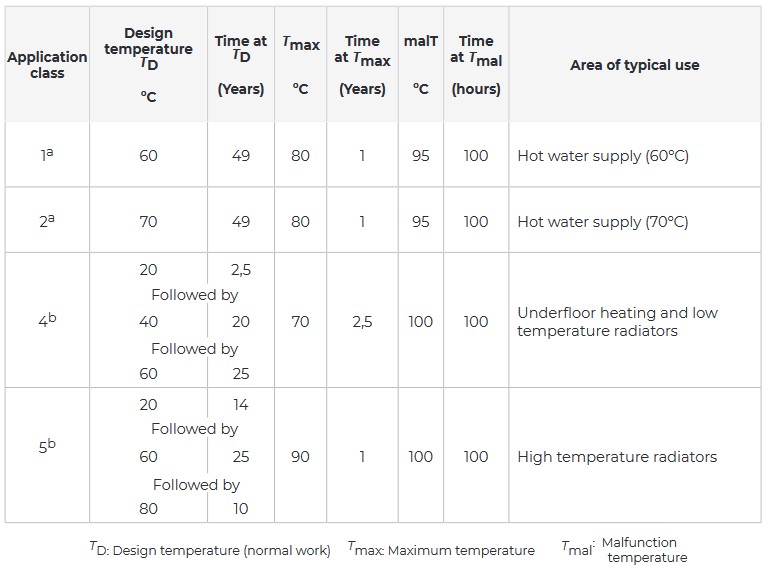

FIELDS OF APPLICATION

a A country may select either class 1 or class 2 to conform to its national regulations

b Where more than one design temperature appears for any class, the times should be

aggregated (for example: the design temperature profile for 50 years of class 5 is: 20ºC for 14 years, followed by 60ºC for 25 years, 80°C for 10 years, 90°C for 1 year and 100°C for 100 hours). This allows to simulate approximate real temperatures and times during a useful life of 50 years.

The design pressures of each application are

PEX-a and evalPEX-a

Series 5,0: class 1 / 6 bar; class 2 / 6 bar; class 4 / 8 bar; class 5 / 6 bar. Cold water: (20 ºC) 15 bar.

Series 4,0: class 1 / 8 bar; class 2 / 8 bar; class 4 / 10 bar; class 5 / 8 bar. Cold water: (20 ºC) 18 bar.

Series 3,2: class 1 / 10 bar; class 2 / 10 bar; class 4 / 10 bar and class 5 / 10 bar.

——————-

Series 5,0: 16×1,5, 20×1,9, 25×2,3, 32×2,9, 40×3,7, 50×4,6, 63×5,8, 75×6,8

Series 4,0: 16×1,8

ASSEMBLY STEPS

1 It is very important to cut the pipe as clean and perpendicular as possible to its axis.

The pipe ends should be dry and without grease, so that the plastic ring will not slide on the pipe during expansion.

2 Fit the plastic ring on the end of the pipe so that a very small part of it (max. 1mm) is outside the pipe end.

The plastic ring should be firmly fitted on the pipe. If the plastic ring fits loosely, expand the pipe end slightly without the plastic ring. Then push the plastic ring back into its correct position.

3 Open the expander tool handles fully and insert the expanding head straight into the

pipe as far as possible.

4 Gradually press the handles together fully. On 20mm and larger pipe sizes, keep the handles together for around 3 seconds.

Open the handles entirely again while withdrawing the expander tool slightly, so

that the jaws will be clear of the pipe wall.

Spin the tool lightly (up to 45º) and insert the jaws back into the pipe as far as possible.

Repeat these steps until the flat parts of the jaws are all the way inside the pipe, i.e. the edge at the end of the flat part strikes the pipe when the jaws are pushed into the pipe.

Expand the pipe by pressing the handles together, one last time

5 Open the handles, remove the expander tool and directly push the pipe onto the fitting

nipple. The plastic ring on the pipe end must reach entirely the shoulder