Technical information

Certificates

Request information

Tuberías AC-FIX PEX-a

DESCRIPTION

The AC-FIX PEX-a and evalPEX-a pipes are made of high density polyethylene according to the Engel process. This process gives the pipe exceptional properties of flexibility, elasticity and resistance to

pressure and temperature. The Engel process is the best manufacturing method that guarantees 100% that the pipe can expand and contract correctly in total safety with the AC-FIX PLASTIC RING EXPANSION fittings.

The AC-FIX PEX-a pipes are composed of a layer of PEX-a according to the UNE-EN ISO 15875-1 standard for hot and cold water installations (sanitary water installations and heating installations *).

The AC-FIX eval-PEX-a pipes are composed of three layers: a layer (base tube) of PEX-a, an intermediate adhesive layer and an outer layer of Ethylvinyl-Alcohol (abbreviated as “EVAL” or “EVOH”) which serves as an anti-oxygen diffusion barrier.

Product certified by AENOR according to the standards UNE-EN ISO 15875-1 and UNE-EN ISO 15875-2.

The AC-FIX PEX-a and evalPEX-a pipes are compatible with the fittings and valves AC-FIX PLASTIC

EXPANSION RING, PRESS, PRESS DUO and SLIDING RING. They are also compatible with UPONOR ® Quick and Easy ® fittings and valves **

The AC-FIX PEX-a pipes 16×1,5 are only compatible with the fittings and valves AC-FIX PRESS and SLIDING RING, neither with the PLASTIC EXPANSION RING nor PRESS DUO

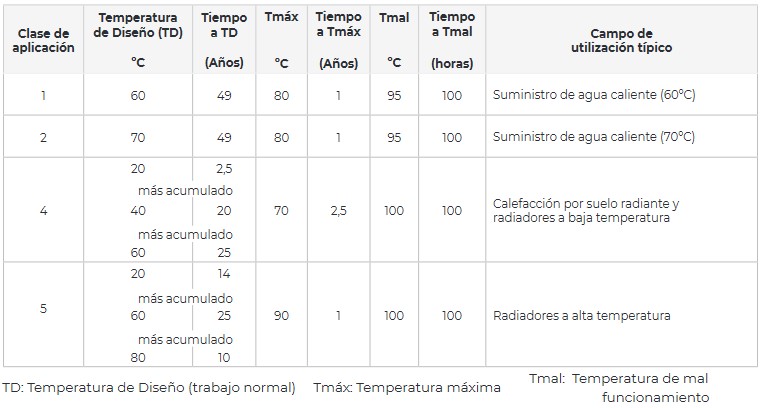

FIELDS OF APPLICATION FOR A DESIGN PERIOD OF 50 YEARS (UNE-EN ISO 15875)

a A country may select either class 1 or class 2 to conform to its national regulations.

b Where more than one design temperature appears for any class, the times should be aggregated (for example: the design temperature profile for 50 years of class 5 is: 20ºC for 14 years, followed by 60ºC for 25 years, 80°C for 10 years, 90°C for 1 year and 100°C for 100 hours). This allows to simulate approximate real temperatures and times during a useful life of 50 years.

The design pressures of each application are:

PEX-a and evalPEX-a

Series 5,0: class 1 / 6 bar; class 2 / 6 bar; class 4 / 8 bar; class 5 / 6 bar. Cold water: (20 ºC) 15 bar.

Series 4,0: class 1 / 8 bar; class 2 / 8 bar; class 4 / 10 bar; class 5 / 8 bar. Cold water: (20 ºC) 18 bar.

———————-

Series 5,0: 16×1,5, 20×1,9, 25×2,3, 32×2,9, 40×3,7, 50×4,6, 63×5,8, 75×6,8

Serie 4,0: 16×1,8

**: Trademark(s) belonging to a third party wich has no link to AC-FIX group of companies.

ADVANTAGES OF PEX-a:

- Very high flexibility due to the production type of PEX-a according to the Engel method.

- Very high degree of crosslinking (> 80%) and consequently, higher resistance to pressure and temperature.

- Low pressure drop and low acoustic transmission.

- Drinking water quality. Completely non-toxic.

- Resistance to the actions applied in the prevention and control of legionellosis.

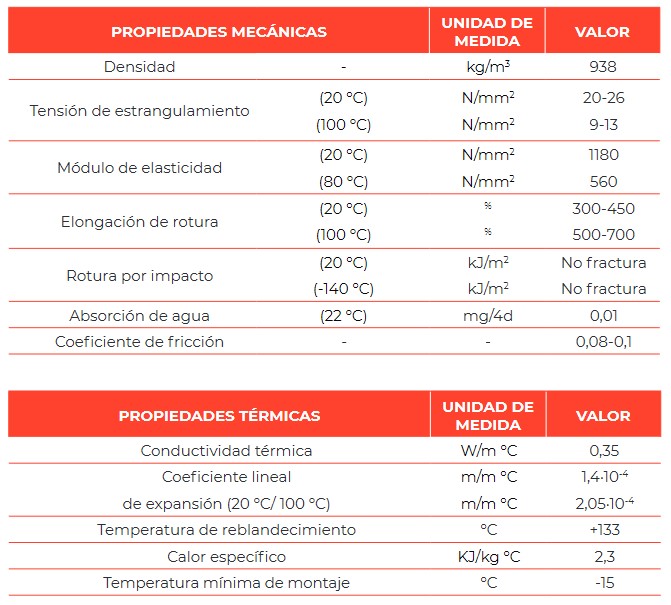

PEX-a PROPERTIES:

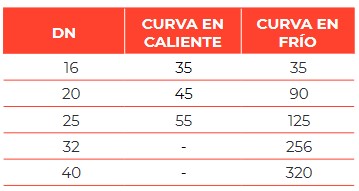

RECOMMENDED BEND RADII IN MILLIMETERS

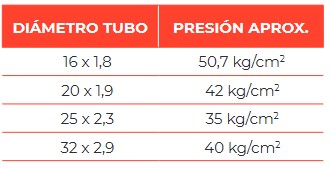

BURSTING PRESSURE A +20 ºC